RPWORLD Further Improves Inspection Speed with New 3D Laser Scanning Machine

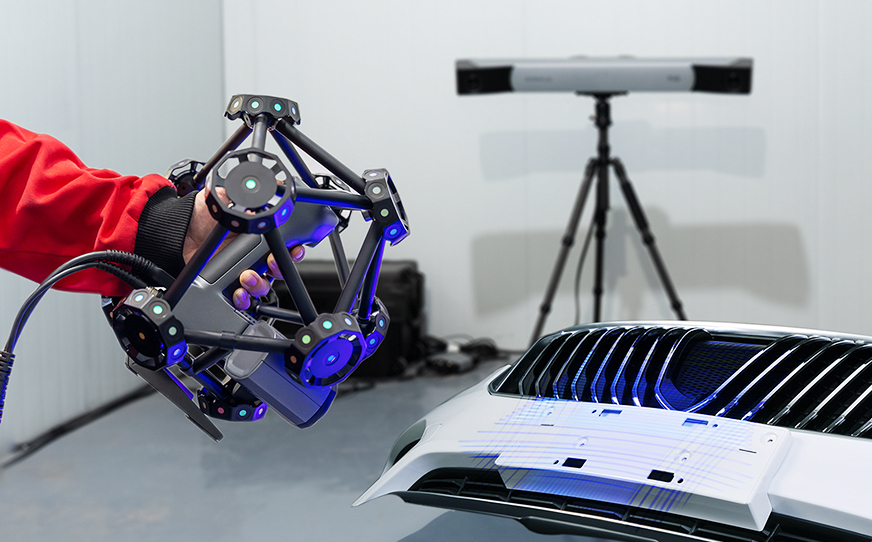

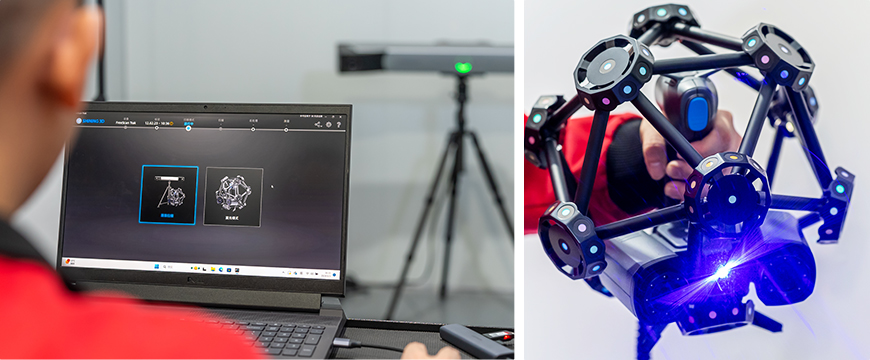

The state-of-the-art 3D laser scanning machine, utilizes laser technology to accurately capture the dimensions and geometries of complex parts. Its dynamic tracking capability ensures high precision in scanning, making it ideal for our customized and precision-demanding parts.

The integration of this advanced equipment into our quality inspection process offers great benefits to our clients:

Cost and Time Efficiency: The precise laser scanning capabilities accelerates our quality control processes. This leads to faster production times, directly translating into cost savings and quicker project turnarounds for our clients.

Increased Consistency: The new inspection machine at RPWORLD further ensures the consistent part specifications for customized parts. This consistency is vital for precision-demanding industries like medical, automotive, and robotics.

Unmatched Precision: The addition of the advanced machine further guarantees exceptional accuracy in part dimensions and geometries, meeting the most critical requirements of part applications.

At RPWORLD, we are dedicated to constantly upgrading our equipment and processes to ensure consistent high-quality parts. From multiple manufacturing processes to a range of finishing options and stringent quality control, we have always prioritized quality at every step. The addition of the 3D Laser Scanning System to our quality assurance exemplifies this dedication, ensuring the rapid delivery of precision-manufactured parts tailored to the evolving needs of our clients.

Tags: Quality Control Process Quality Assurance XRF Analyzer

INQUIRY

MOST POPULAR

- Congratulations to INNORAPID LIMITED for Obtaining "High-tech Enterprises Certification"!

- Know the Content of Materials, Get Better Products!

- The 6th Anniversary Gala of Changsha Office, RPWORLD

- Analysis of UL Flammability Standards I

- Inspect Faster & More Accurately—RPWORLD Upgraded Inspection Capability Again

- Sustainable Manufacturing at RPWORLD

15 January, 2024

15 January, 2024